“I was always riled by the fact that the bending machine wasn’t stable” …

… remembers Kurt Jorns, the founder of Jorns AG and developer of the machine frame. After all, a bending machine weighs several tons and has to get to the customer safely and be installed there correctly to produce exact bending results. In the 1970s, the qualified master mechanic Kurt Jorns was still installing bending machines at his customers’ premises himself – and he had an idea.

Planning work on the drawing board: Kurt Jorns and employee, 1973 | © Jorns AG

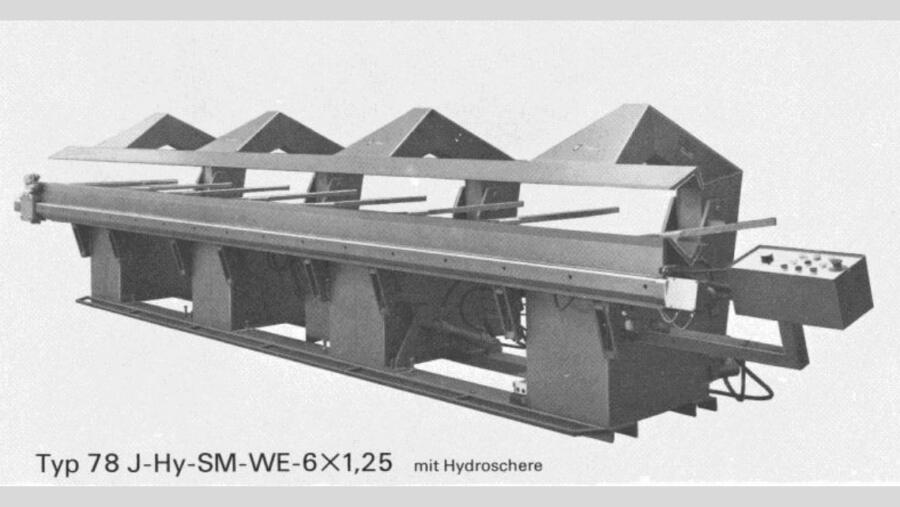

The new standard 1975: type 78 bending machine rests on the clearly visible machine frame | © Jorns AG

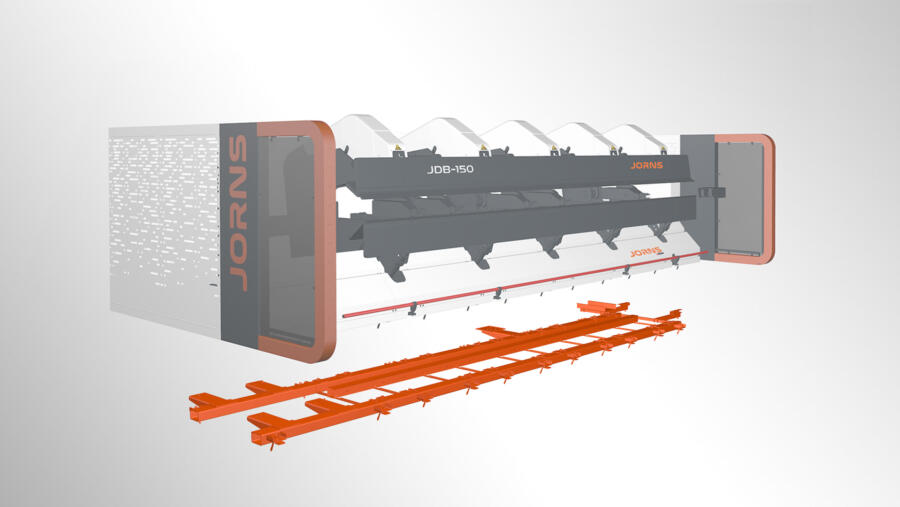

The same principle: what the machine frame looks like today before installation | © Jorns AG

JB 150 bending machine – with integrated machine frame, invisible behind the panel | © Jorns AG

First the definition: what is the machine frame on a bending machine?

The machine frame today is the basis of any bending machine: it simplifies transport and permits simple and very precise levelling of the bending machine.

Kurt Jorns, on what kind of base did bending machines stand in the 1970s – how were they installed at the customer’s premises?

Kurt Jorns: Well, the stands were bolted to the floor separately and had to be underlaid with small metal plates so that the machine was level.

What exactly did you notice during the installation without a machine frame? What were the disadvantages of this? Were there any advantages too?

It was above all very inconvenient for transportation, because long machines in particular were not very stable without a machine frame. The only advantage without the frame was the lower cost of the machine’s manufacture.

When did you come up with the idea of changing something?

When we started out, I used to install the machines myself. And I was always riled by the fact that the bending machine wasn’t stable during transportation and that its installation was very awkward. It proved particularly difficult to install the machines on uneven floors on the customers’ premises – often they couldn’t be placed directly in their final position with a crane. And sliding them over the floor without a machine frame was very nearly impossible.

Did you know of any competitors’ products that already had a machine frame?

At that time, Jorns was one of the first companies to fit a machine frame. Tensol, a former Swiss competitor, for example, still had no machine frame long after this was already a standard feature on our machines. Jorns was one of the first companies to use a machine frame for long bending machines.

How did you develop the machine frame at Jorns?

I came up with the further developments myself on the drawing board before implementing them in production. I discussed my idea with the foreman and then put it into practice. We didn’t need a prototype – we decided to make it a standard feature straight away.

In what year was this, and how many people were there in the Jorns workshop?

That was in 1973, and there were around 15 to 20 people working in the company.

What specific device did you then develop, what was it made of and how was it fastened to the machine?

I knew straight away that it would have to be a C-profile fitted with alignment and fastening bolts, and that it would need plates beneath the alignment bolts. This was the only way to ensure a better alignment and easier transportation of the machine. What’s more, the C-profile was a low-cost profile that was readily available on the market at that time. In the beginning, the C-profiles were welded to the stands. It wasn’t until the 1990s that we started milling the stands and bolting them to the machine frame, just like in today’s system.

When did you deliver and install the first bending machine with a machine frame?

That would have been in the mid-1970s, shortly after we took over the firm of Konrad in 1973.

What feedback did you receive from customers?

Our customers were highly delighted with the set-up because the machines were easier to transport thanks to their improved stability. And the bending results improved too because this made it easier to align and adjust the machines.

What has changed since then on the Jorns machine frames?

The machine frames are now aligned even more precisely before and after processing. Apart from that, the machine frames on today’s Jorns bending machines are the same as the first ones. The only difference is that we now use tubes for the machine frames on Jorns double bending machines, giving these heavy machines even more stability.

How did you feel after this development? What other technical changes did you suggest?

First and foremost, I was relieved that it was now easier and safer to install the machines. Only later did we introduce the first hydraulic actuators, the first NC and CNC controllers, the depth stop and various other options.

Thank you for the interview, Kurt Jorns!

The man behind the name: Kurt Jorns, founder of Jorns AG, born 1940, qualified mechanic and master machine builder; took over the mechanical engineering firm of Konrad in 1973, who built the first long manual bending machines; founded today’s firm of Jorns in the same year with his wife Margrith Jorns; 2005 handed over the company to the second generation – Nicole Jorns and Marc Jorns.

Did you know that you can also message the machine frames? We would be happy to tell you more.