Jorns bending machine: graphically controlled and inspiring

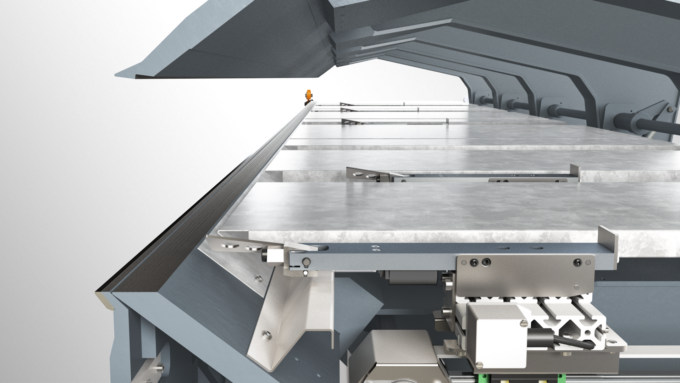

The semi-automatic Jorns JB bending machine can be configured in lengths of 3.2 to 12.2 metres and with a bending capacity for sheet metal up to 3 mm. It offers a great deal of freedom – and not only when it comes to the clamping tool.

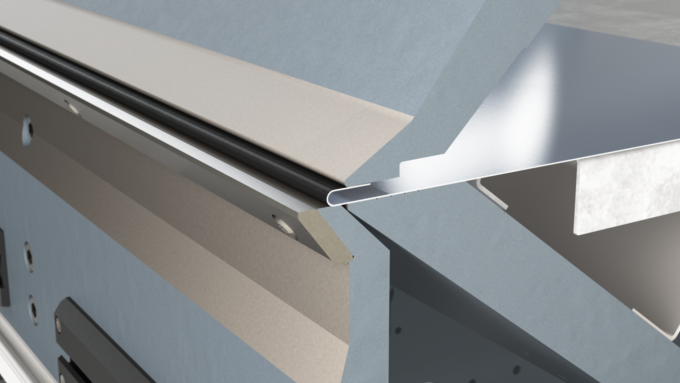

The area in front of and behind the clamping tool of the Jorns JB bending machine offers above-average open space, letting you manufacture bending profiles extremely efficiently. The use of servo-technology and the stop fingers that can be moved freely on the sides guarantee maximum precision and flexibility to bend parallel, tapered or overlapped profiles.

A successful bend and subsequent installation of your profiles is down in no small part to the consistent calculation of processing and stop positions according to the “Shorten bending according to DIN 6935” method, intuitive graphic programming, the high level of angular accuracy and the uniformly closed water folds. Ultimately, what the JB gives you is time – time for more freedom and new ideas in your projects.

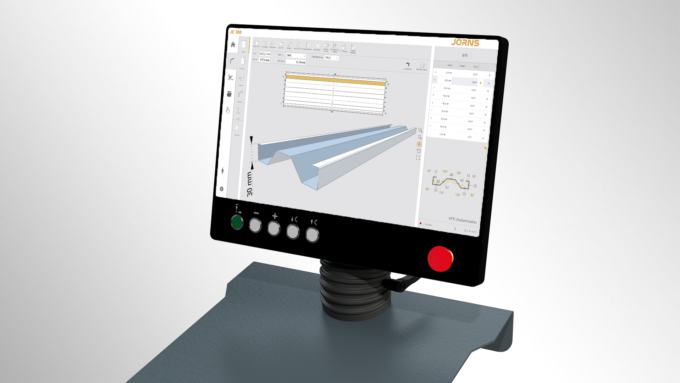

JC100 graphics control: with multi-nesting function

This control is the basis for the entire configuration of your bending machine. It is responsible for the very high dimensional and angular accuracy and ensures a particularly fast result from the sketch to the profile; an automatic springback compensation is integrated. The advantage: profile samples no longer occur in the work process – the first result is immediately and exactly correct.

The multi-nesting function is particularly useful if, for example, you want to produce a multi-pluggable tappered bending profile that is longer than the maximum bending length of your bending machine. With the help of this function, you can define the planned profile in sketch mode. The result consists of several bending parts that are connected by plugging them together.

For example, you can produce a 20-metre long sloping gutter consisting of four parts: First, define the desired side lengths – at the profile end of the profiles that will ultimately be connected – in sketch mode. At the push of a button, the control system automatically calculates and then creates the sub-profiles. In the next step, you can join the four different parts into a perfect whole by means of their exact pluggability. In the process, the direction of insertion, depth of overlap and tapering of the overall profile are taken into account.

The multi-nesting function of Jorns bending machines not only saves you a great deal of time with these complex tasks, but also reduces material costs. You can completely dispense with the usual trial and error and the creation of profile samples.

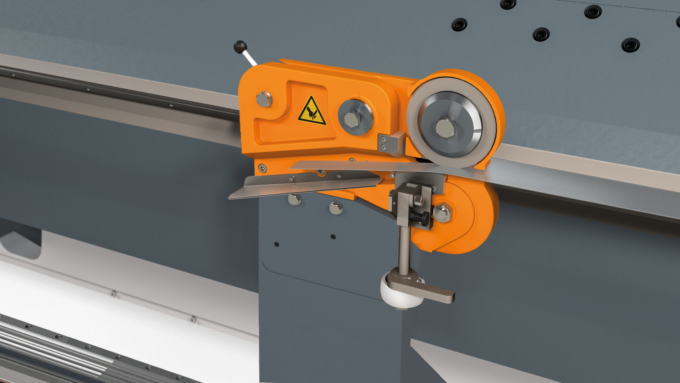

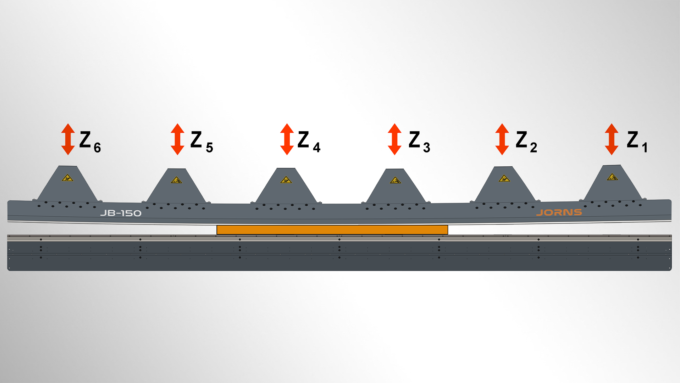

Bending machine with super-stable back stop system

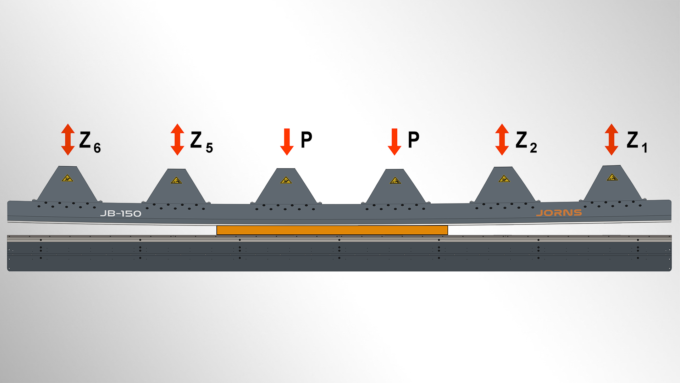

The back stop system of all Jorns bending machines is extremely stable and robust - a real powerhouse that takes great precision. The back stop fingers are not only free movable over the entire length, but in the type 11 and type 20 back stop systems the stop fingers are provided with a hardened stop edge. Even when things get hectic in the work process, they remain calm and ensure the highest positioning accuracy of +/- 0.1 millimeters. The adjustment speed is up to 366 millimeters per second.

The automatic back stop system type 11 is complemented by the back stop system type 11, tapered, which can be added to the right side of the machine either at the time of purchase or at a later date; this also allows you to produce conical or pluggable profiles. Even more convenient: Select the back stop system type 20, tapered – this system can bend tapered profiles right out of the box. Here you program the planned tapered or pluggable profiles directly via the control system.

As you can see, the advantages add up. And the bottom line is that with the Jorns JB bending machine you gain time – for more project freedom and new ideas.

From modular machine design to personalisation.

Each Jorns JB bending machine comes with first-class basic equipment that can be personalised thanks to the modular machine design. You then configure the bending machine according to your personal requirements and planned applications. Regardless of the length, bending capacity, control system or shears you choose, the basic equipment remains the same on all machines. It offers the highest levels of precision, lots of freedom and maximum safety.

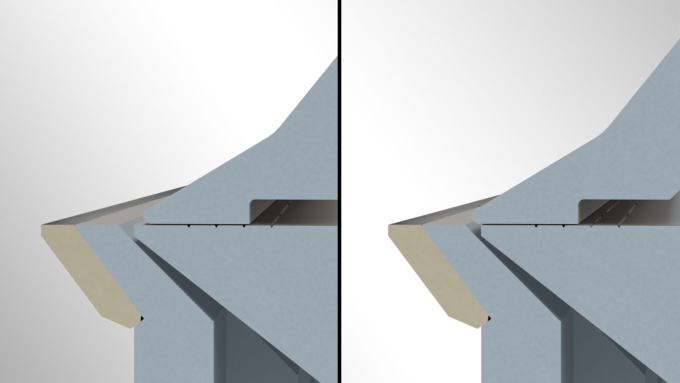

Mechanical machine design

With its robust construction and box-shaped welded design, the Jorns JB bending machine is set up for the rigours of long-term operation. The solid bending joints have a maximum bending angle of up to 145° and accurate bending angles across the entire working length. The high clamping force required for a precise bend and closed hems can be achieved using the clamping cylinders installed on every clamping arm. The clamping cylinders can be controlled individually. This not only allows for a parallel mechanical closing of the clamping tool but also pre-tensioned closing – the material springback seen when press-closing the hems is compensated for. The result is parallel hems tailored to the profile.

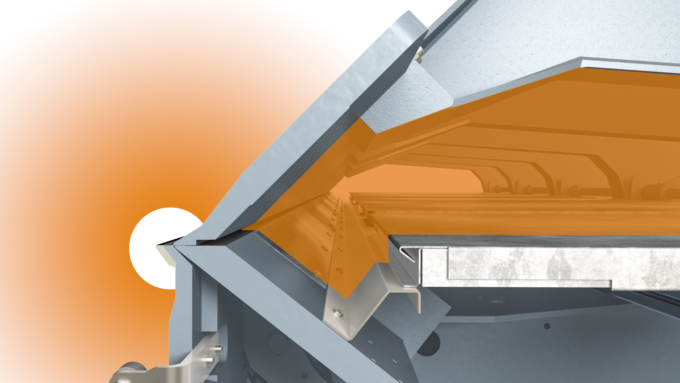

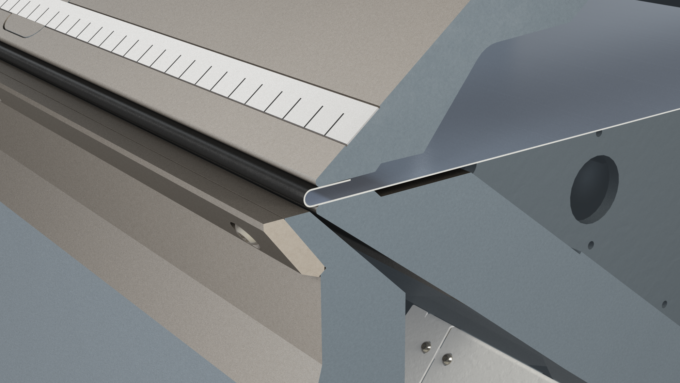

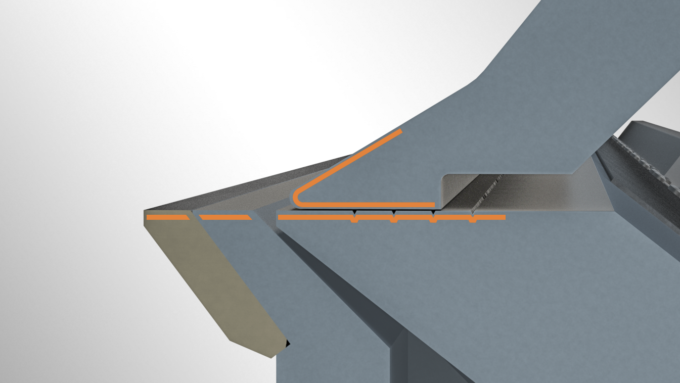

Tool geometry

The sophisticated machine design also includes the “G” tool geometry, which has open space of 275° between the upper beam and bending beam in front of the machine. Contoured by 37°, the bending tool allows for the production of precise 90° hat-shaped profiles and overlapped profiles used for cladding. The clamping tool is positioned at a 45° angle and has a large open space in order to be able to position the pre-bent profiles as close to the clamping point as possible. The sheet cassettes in the machine can be moved horizontally and vertically, and offer additional open space below the clamping line for pre-bent profiles.

Machine safety

The basic equipment of the Jorns JB bending machine is supplemented by a sophisticated safety system. The highest levels of safety are guaranteed at all times without restricting everyday work on the machine, even when processing corrugated material. The use of a three-ray laser system reduces the risk of accidents when closing the clamping tool and when using the shears to a minimum.

Individual machine configuration

The modular mechanical design of the Jorns JB bending machine lays the foundations for a personalised machine configuration – one that is perfect for your needs. You define the length from 3.2 to 12.2 metres, the bending capacity for sheet metal up to 3 mm, the control system, back stop system, shears and other options that should be used. Take a look at our online configurator ((Link?)) or get in touch with us directly – we would be happy to help.

The area in front of and behind the clamping tool of the Jorns JB bending machine offers above-average open space, letting you manufacture bending profiles extremely efficiently. The use of servo-technology and the stop fingers that can be moved freely on the sides guarantee maximum precision and flexibility to bend parallel, tapered or overlapped profiles.

A successful bend and subsequent installation of your profiles is down in no small part to the consistent calculation of processing and stop positions according to the “Shorten bending according to DIN 6935” method, intuitive graphic programming, the high level of angular accuracy and the uniformly closed water folds. Ultimately, what the JB gives you is time – time for more freedom and new ideas in your projects.

JC100 graphics control: with multi-nesting function

This control is the basis for the entire configuration of your bending machine. It is responsible for the very high dimensional and angular accuracy and ensures a particularly fast result from the sketch to the profile; an automatic springback compensation is integrated. The advantage: profile samples no longer occur in the work process – the first result is immediately and exactly correct.

The multi-nesting function is particularly useful if, for example, you want to produce a multi-pluggable tappered bending profile that is longer than the maximum bending length of your bending machine. With the help of this function, you can define the planned profile in sketch mode. The result consists of several bending parts that are connected by plugging them together.

For example, you can produce a 20-metre long sloping gutter consisting of four parts: First, define the desired side lengths – at the profile end of the profiles that will ultimately be connected – in sketch mode. At the push of a button, the control system automatically calculates and then creates the sub-profiles. In the next step, you can join the four different parts into a perfect whole by means of their exact pluggability. In the process, the direction of insertion, depth of overlap and tapering of the overall profile are taken into account.

The multi-nesting function of Jorns bending machines not only saves you a great deal of time with these complex tasks, but also reduces material costs. You can completely dispense with the usual trial and error and the creation of profile samples.

Bending machine with super-stable back stop system

The back stop system of all Jorns bending machines is extremely stable and robust - a real powerhouse that takes great precision. The back stop fingers are not only free movable over the entire length, but in the type 11 and type 20 back stop systems the stop fingers are provided with a hardened stop edge. Even when things get hectic in the work process, they remain calm and ensure the highest positioning accuracy of +/- 0.1 millimeters. The adjustment speed is up to 366 millimeters per second.

The automatic back stop system type 11 is complemented by the back stop system type 11, tapered, which can be added to the right side of the machine either at the time of purchase or at a later date; this also allows you to produce conical or pluggable profiles. Even more convenient: Select the back stop system type 20, tapered – this system can bend tapered profiles right out of the box. Here you program the planned tapered or pluggable profiles directly via the control system.

As you can see, the advantages add up. And the bottom line is that with the Jorns JB bending machine you gain time – for more project freedom and new ideas.

Defining the machine capacity.

The time has come to configure your very own Jorns JB bending machine according to your wishes and demands. By defining the maximum bending capacity and maximum bending length, you can specify the size of your future Jorns JB bending machine. Does the available selection not meet your expectations? If so, please contact us. We would be happy to offer a system in the size you require.

Bending capacity

1.25 mm Steel 0.80 mm Inox 2.00 mm Aluminium

Bending length

The control system – tailored to your demands.

The control system is the variable nerve centre of the Jorns JB bending machine. It adapts to your requirements and your demands – and not the other way around. Below, you can see in detail what all of the control systems have to offer. What they all have in common is that they can be operated intuitively.

The back stop system: automatic, tapered or manual?

A stable, variable back stop system is decisive when it comes to producing precise bending profiles. On all our back stop systems, the stop fingers can be moved and positioned freely on the sides across the entire length, thus ensuring the very highest degree of flexibility. The following back stop systems are available on your Jorns JB bending machine:

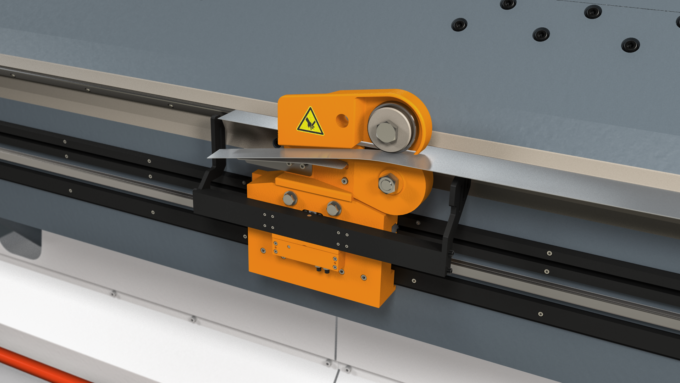

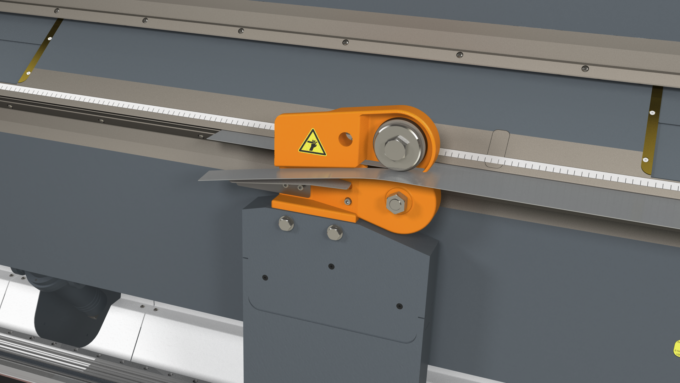

Shears – precise and safe both in semi-automatic and fully automatic mode.

Durable and reliable shears are absolutely essential for the accurate cutting of a parallel or tapered sheet strip, not to mention a precise edge profile. Which cutting performance do you require? Choose one of our shear systems for your Jorns JDB double bending machine.

How do you want to work? At normal speeds or with a 30 percent increase in speed and productivity?

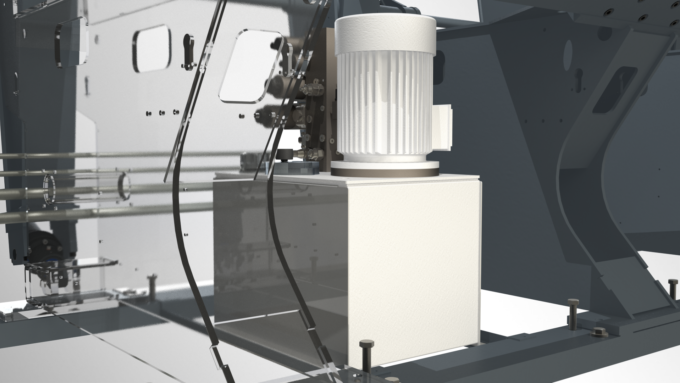

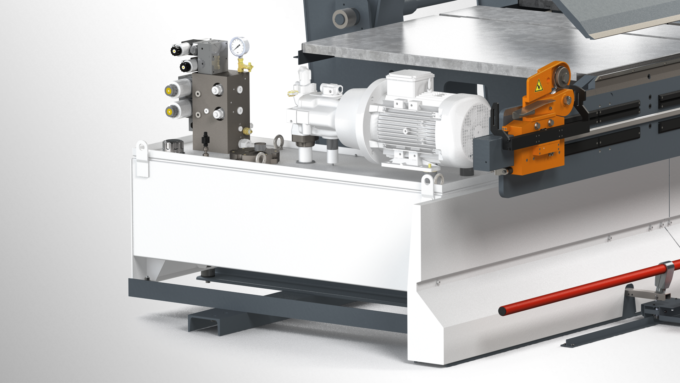

What are your plans for using the Jorns JB bending machine? If you only plan on using it sporadically, then the hydraulic system in the basic equipment is perfect for your needs as it offers a good basic speed. However, if your Jorns JB bending machine is in use for several hours a day, then you can increase its productivity by 20 to 30 percent with a more powerful hydraulic system.

Using software to get the most out of your Jorns JB bending machine.

In the Jorns JB bending machine, you have chosen an extremely powerful machine that can do a great deal. But that’s not all! The software developed in-house at Jorns for offline programming and the J-Bend app can be used to exploit the full potential of the machine. The following software also offers exceptional support when using the latest JC100 control system on the Jorns JB bending machine.

Further options for making your Jorns JB bending machine even more versatile.

Thanks to the modular machine design, your Jorns JB bending machine can be customised to your individual needs with the following optional extras. For example, maybe you want to do something against dents on the bending tools when bending materials with increased hardness on the edge layer? How about ensuring perfect bends automatically thanks to an optimally set air gap? Or maybe you want to prevent increased springback or create accurate, parallel open hems.

Instantly in the picture: useful videos and clips on your Jorns JB bending machine.

Videos, clips and tutorials on our Jorns JB bending machine give an insight into the basic and specialist knowledge involved in the machine functions, technology and software.

Jorns JB bending machine: Maximum flexibility thanks to optimum tool geometry

Jorns JB bending machine: flexibility thanks to freely selectable position of the back stop fingers

Jorns JB bending machine: Maximum productivity thanks to modular machine design

Jorns JB bending machine: Shearing systems – precise and safe

Jorns JB bending machine: High safety standard without losing flexibility

Jorns JB bending machine: Precise hems thanks to unique technology

Jorns JB bending machine: back stop system type 14, tapered for maximum precision

Request a quote

Configure the machine according to your needs. Start configurator

Did you not find something? We realize individual wishes.

The Jorns Sales-Team

Phone +41 62 919 80 50