The Jorns JDB double bending machine: adrenalin-driven.

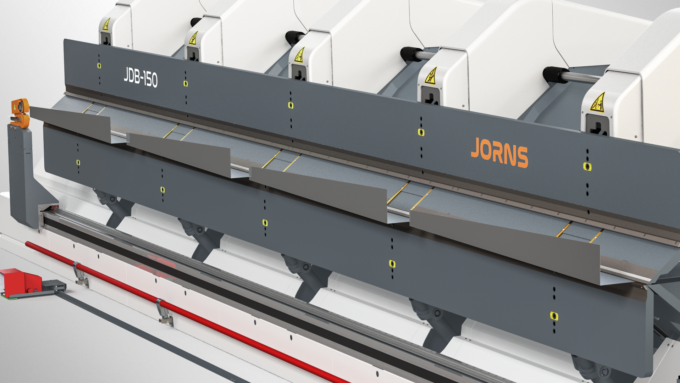

The fully automatic Jorns JDB double bending machine can be configured in lengths of 3.2 to 12.2 metres and with a bending capacity for sheet metal up to 3 mm. It increases the speed of your projects – and awakens the desire to create something bigger.

The simultaneous bending of complex profiles poses no problem for the Jorns JDB double bending machine because multitasking is a given. The area behind the clamping tool with a retraction of over 290 mm for the bending tools offers above-average open space. You can then produce bending profiles without turning them around or over – with an array of possible profile variations. Several parallel, tapered or overlapped profiles can be bent simultaneously, an innovation that increases the speed of your work.

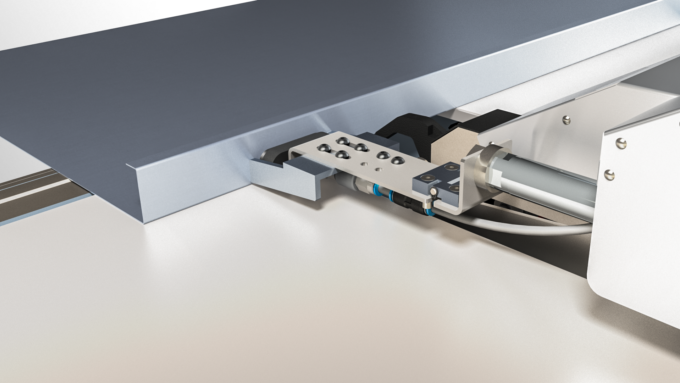

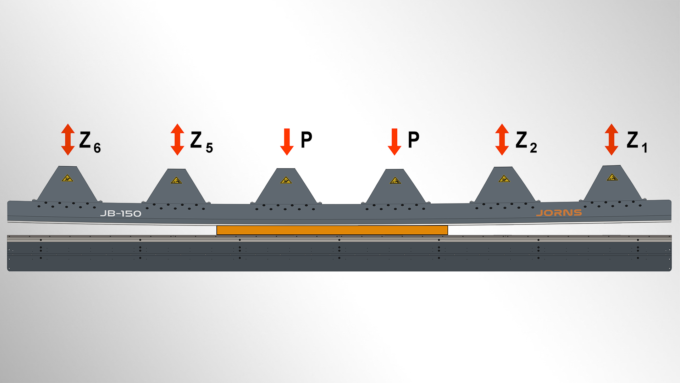

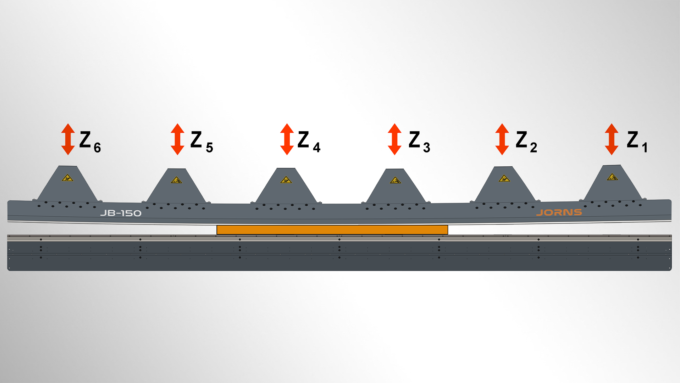

The use of servo-technology, the automatic loading and unloading table as well as the individually driven clamping fingers allow maximum precision, flexibility and productivity. Thanks to two bending tools, material handling has also been drastically reduced. The consistent calculation of processing and stop positions according to the “Shorten bending according to DIN 6935” method, intuitive graphic programming, high level of angular accuracy and the uniformly closed water folds are all an integral part of the JDB. If you had a passion for creating something before, then just watch this grow in future.

From modular machine design to personalisation.

Each Jorns JDB double bending machine comes with first-class basic equipment that can be personalised thanks to the modular machine design. You then configure the double bending machine according to your personal requirements and planned applications. Regardless of the length, bending capacity, back stop system, shears or other options you choose, the basic equipment remains the same on all machines. It offers the highest levels of precision, lots of freedom and maximum safety.

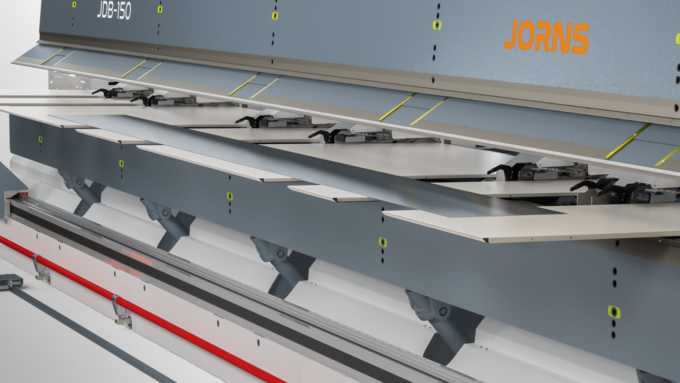

Mechanical machine design

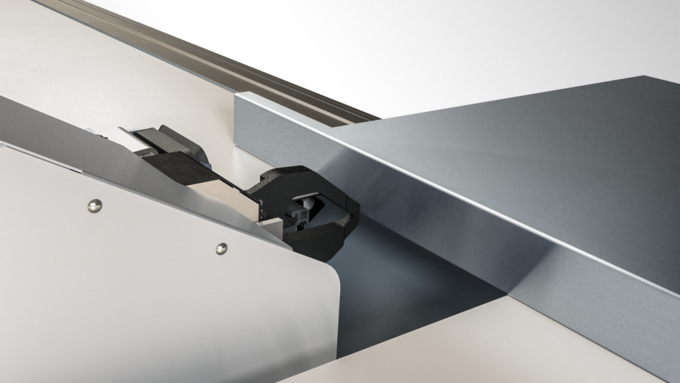

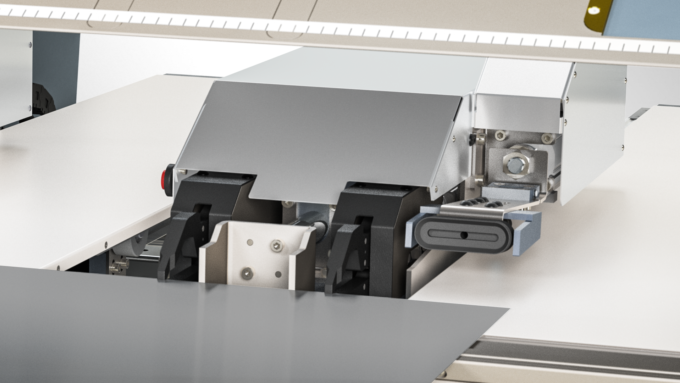

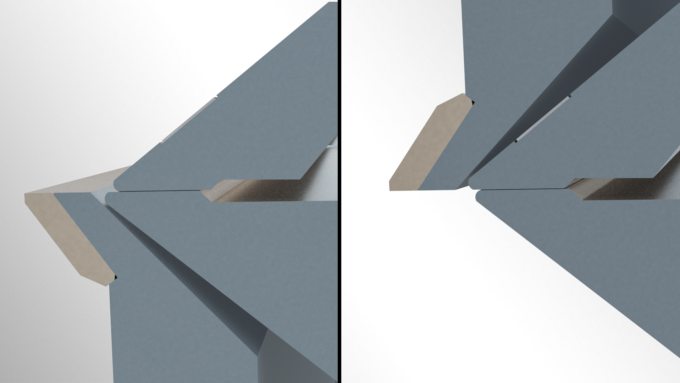

With its robust construction and box-shaped welded design, the Jorns JDB double bending machine is set up for the rigours of long-term operation. The hydraulic bending joints on each stand (or arm) have a maximum bending angle of up to 145° and accurate bending angles across the entire working length. The high clamping force required for a precise bend and closed hems can be achieved using the clamping cylinders installed on every clamping arm. The clamping cylinders can be controlled individually. This not only allows for a parallel mechanical closing of the clamping tool but also pre-tensioned closing – the material springback seen when press-closing the hems is compensated for. The result is parallel hems tailored to the profile.

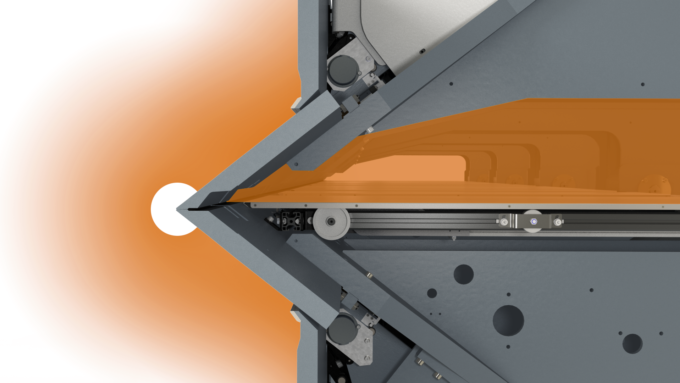

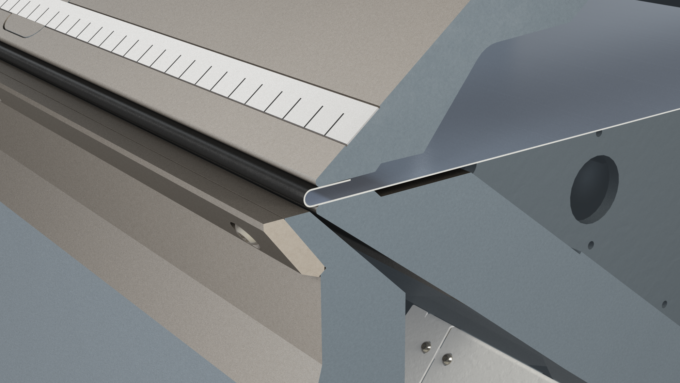

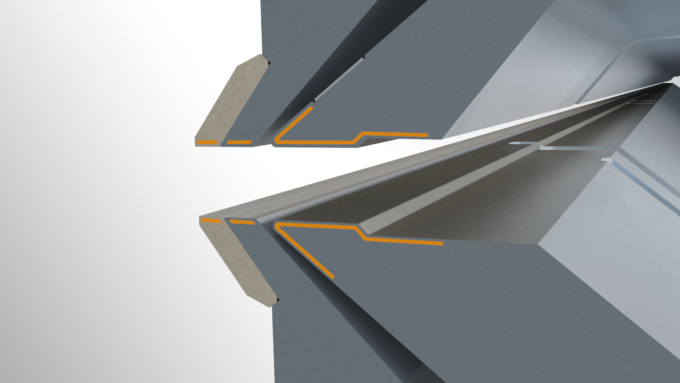

Tool geometry

The sophisticated machine design also includes the “G” tool geometry, which has open space of 269° between the clamping tool and bending tool in front of the machine. Contoured by 37°, the bending tool allows for the production of precise 90° hat-shaped profiles and overlapped profiles used for cladding. The bending tools can be retracted by 290 mm and create the largest possible space in front of the machine. A wide variety of profiles can then be manufactured without turning them around or over. The clamping tool is positioned at a 38° angle and has a large internal open space in order to be able to position the pre-bent profiles as close to the clamping point as possible.

Machine safety

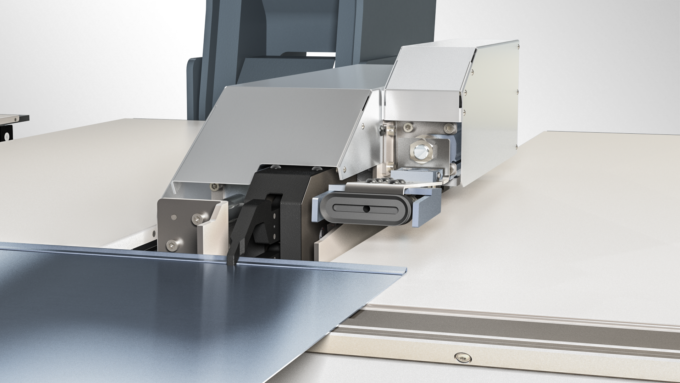

The basic equipment of the Jorns JDB double bending machine is supplemented by a sophisticated safety system. The highest levels of safety are guaranteed at all times without restricting everyday work on the machine, even when processing corrugated material. The safety equipment on the machine and the light barriers used ensure safe, fully automatic operation. The use of a three-ray laser system reduces the risk of accidents when closing the clamping tool and when using the shears in semi-automatic operation.

Individual machine configuration

The modular mechanical design of the Jorns JDB double bending machine lays the foundations for a personalised machine configuration – one that is perfect for your needs. You define the length from 3.2 to 12.2 metres, the bending capacity for sheet metal up to 3 mm, the back stop system, shears and other options that should be used. Take a look at our online configurator or get in touch with us directly – we would be happy to help.

The simultaneous bending of complex profiles poses no problem for the Jorns JDB double bending machine because multitasking is a given. The area behind the clamping tool with a retraction of over 290 mm for the bending tools offers above-average open space. You can then produce bending profiles without turning them around or over – with an array of possible profile variations. Several parallel, tapered or overlapped profiles can be bent simultaneously, an innovation that increases the speed of your work.

The use of servo-technology, the automatic loading and unloading table as well as the individually driven clamping fingers allow maximum precision, flexibility and productivity. Thanks to two bending tools, material handling has also been drastically reduced. The consistent calculation of processing and stop positions according to the “Shorten bending according to DIN 6935” method, intuitive graphic programming, high level of angular accuracy and the uniformly closed water folds are all an integral part of the JDB. If you had a passion for creating something before, then just watch this grow in future.

Defining the machine capacity.

The time has come to configure your very own fully automatic Jorns JDB double bending machine according to your wishes and demands. By defining the maximum bending capacity and maximum bending length, you can specify the size of your future Jorns JDB double bending machine. Does the available selection not meet your expectations? If so, please contact us. We would be happy to offer a system in the size you require.

Bending capacity

1.25 mm Steel 0.80 mm Inox 2.00 mm Aluminium

Bending length

The control system: at the heart of your projects.

The intuitive JC100 graphic control system is the nerve centre of the Jorns JDB double bending machine. It is characterised in particular by a clear design and powerful functions based on customer-oriented software development. The JC100 is then not only able to control a fully automatic machine, but can also make the heart beat faster as well.

The back stop system: semi-automatic or fully automatic?

A stable, variable back stop system is decisive when it comes to producing bending profiles quickly and precisely. These two back stop systems are a great help when carrying out bending work with the Jorns JDB double bending machine – and all with exceptional flexibility, precision and performance.

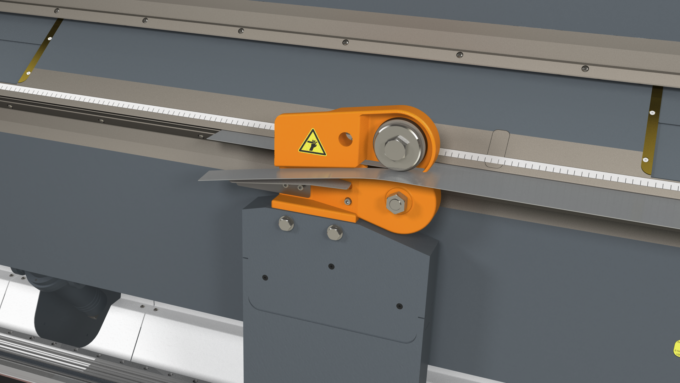

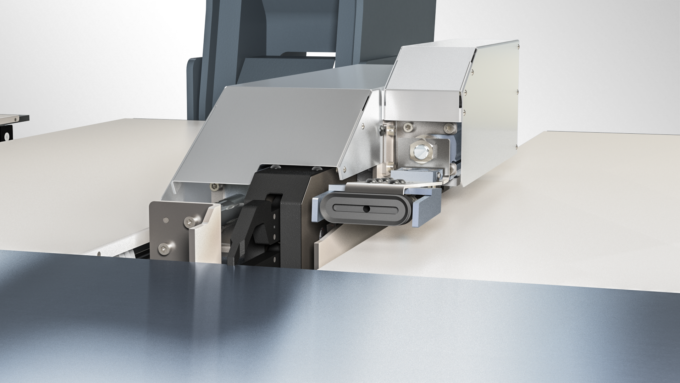

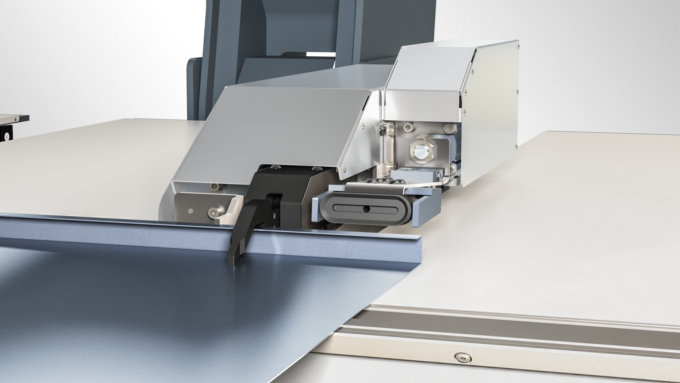

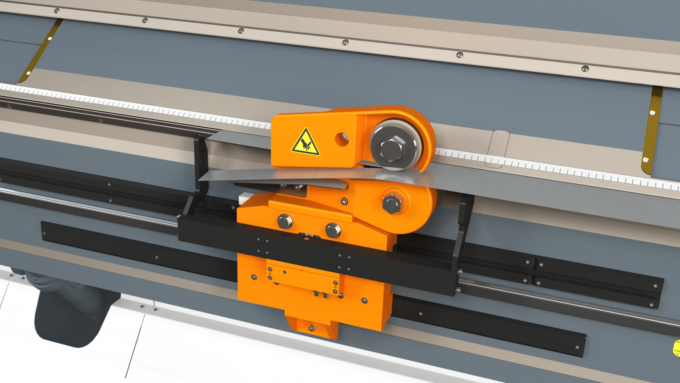

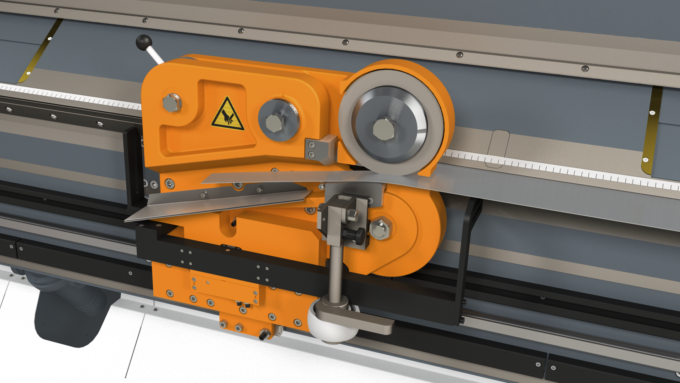

Shears – precise and safe both in semi-automatic and fully automatic mode.

Durable and reliable shears are absolutely essential for the accurate cutting of a parallel or tapered sheet strip, not to mention a precise edge profile. Which cutting performance do you require? Choose one of our shear systems for your Jorns JDB double bending machine.

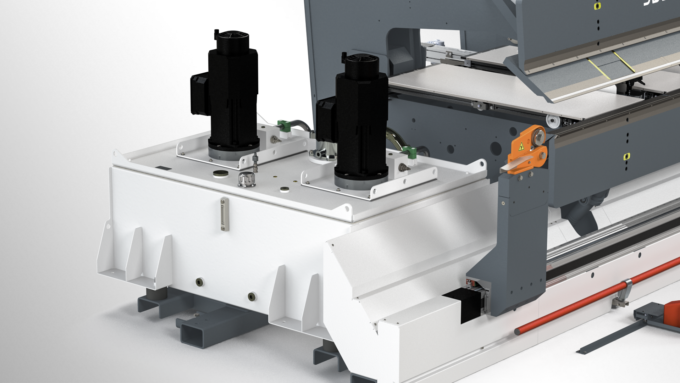

Maximise your machine productivity with the DSP hydraulic system.

What is the most productive way to work with your Jorns JDB double bending machine? By using a high-performance DSP hydraulic system, which can move several axes simultaneously. This speeds up the working process by 30 percent, thus saving you time and maximising your productivity.

Software for using your Jorns JDB double bending machine to its full potential.

In the Jorns JDB double bending machine, you have chosen an extremely powerful machine that can do a great deal. But that’s not all! The software developed in-house at Jorns for offline programming and the J-Bend app can be used to exploit the full potential of the machine. The following software also offers exceptional support when using the latest JC100 control system on the Jorns JDB double bending machine.

Other options for making your Jorns JDB double bending machine even more versatile.

Thanks to the modular machine design, your Jorns JDB double bending machine can be customised with the following optional extras. For example, maybe you want to do something against dents on the bending tools when bending materials with increased hardness on the edge layer? How about ensuring perfect bends automatically thanks to an optimally set air gap? Or maybe you want to create accurate, parallel open hems or load and unload the bending material automatically.

Instantly in the picture: useful videos and clips on your Jorns JDB double bending machine.

Videos, clips and tutorials on our Jorns JDB double bending machine give an insight into the basic and specialist knowledge involved in the machine functions, technology and software.

Jorns JDB double bending machine: Maximum flexibility thanks to optimum tool geometry

Jorns JDB double bending machine: Precise hems thanks to unique technology

Jorns JDB double bending machine: clamping finger electric, tapered for maximum precision

Jorns JDB double bending machine: Shearing systems – precise and safe

Jorns JDB double bending machine: High safety standard without losing flexibility

Jorns JDB double bending machine: Maximum flexibility thanks to flexible clamping system

Jorns JDB double bending machine: Maximum productivity thanks to modular machine design

Request a quote

Configure the machine according to your needs. Start configurator

Did you not find something? We realize individual wishes.

The Jorns Sales-Team

Phone +41 62 919 80 50